DCP FIRE EXTINGUISHER

Oil, Solvents, Gases, Paints Varnish, Electrical Wiring, Live Machinery Fire, All flammable liquid and fires

W-CO2 FIRE EXTINGUISHER: Our range of water type fire extinguisher are suitable for Class A fire. These are used to fight against fire, which involve combustible material of organic nature like wood, paper, textile, jute etc.

Oil, Solvents, Gases, Paints Varnish, Electrical Wiring, Live Machinery Fire, All flammable liquid and fires

Useful for class 'B' & 'C' fires involving materials like fabric, oil spillages and delicate machineries. CO2 extinguishers fire by blanketing dilution of oxygen and cooling effects. B.I.S. Specification: 2878

This ABC fire extinguisher is useful for fires of class A, B & C types which involve wood, cotton, flammable liquids, grease, electrical wiring, live machineries etc. The blanketing effect of ABC powder decomposes fire quickly. B.I.S. Specification: 13849

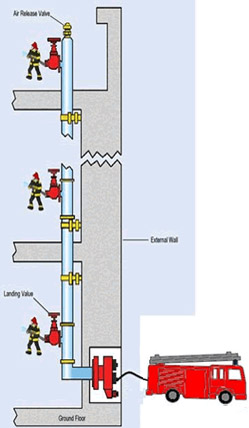

It is a well-designed & well laid hydrant system which extinguish fires of serious proportions in all classes of risks. It has the ability to continues to be in full operation even if part (s) of affected buildings &/ or structures have collapsed & also keeps cool all adjoining properties. It is also a part of hydrant system to provide a pipe permanently charged with water under pressure rising through the full height of the building.

Sprinkler system is most popular system because of it’s vide applications in fire industries. It has two function to perform firstly, it detect a fire and they provide an adequate of water spray only over the vicinity of fire.

Industrial/non industrial buildings, institutional buildings, residential apartments, hotel & hospitals, mall & multi storied complexes, chemical & flammable storage yards

The wet riser systems are permanently charged with water from a header tank above the wet riser system and will be automatically discharged in an event of an outbreak of fire.

The main difference between wet and dry risers is that dry risers systems can only be installed up to 60 metres and are not pressurised with water like wet risers.

Wet riser systems are the pipework system that will carry water to the sprinkler heads in case of a fire. Sprinkler systems are the most reliable and simple as the only operating components being the automatic sprinklers and the automatic alarm check valve. An automatic water supply provides water under pressure to the system piping. All of the piping is filled with water. Until sufficient heat is applied, causing one or more sprinklers to fuse, the automatic sprinklers prevent the water from being discharged.

Wet riser systems are a building regulations requirement in occupied buildings over 60 metres tall and form part of a buildings fire suppression system.

Automatic fire detection and alarm systems are designed to warn building occupants of a fire situation, they do not generally intervene in the fire growth process except where interfaced with a fire suppression or other fire control system. These systems generally use smoke, heat or flame detectors to detect the outbreak of fire and to alert building occupants and the fire brigade. Manual call points which allow an occupant who discovers fire to raise the alarm may also be included in the system.

Single station residential smoke alarms, as installed in most homes, are the simplest system for detecting a fire and warning the building occupants. The time between the outbreak of fire and the commencement of firefighting is the single most important factor in fire control and can be effectively reduced by having the system monitored directly by the fire brigade.

Fire alarm systems must be heard by the building occupants in all parts of the building. To achieve this, they are often connected to occupant evacuation warning and intercommunication systems which sound a defined "beep - beep - beep" throughout the building when the detection system has been activated.

Sometimes these systems automatically close smoke and fire doors, operate flashing warning lights, stop air-conditioning systems or alert critical staff via personal pagers. Today these systems extensively rely upon computer systems and are changing at the same rapid pace as is computer technology. Today's systems can be "intelligent" defining exactly where the fire is, determining if the smoke is from a fire threat or just burnt toast and advising the maintenance manager when the detector needs cleaning or other routine maintenance work is required.

85% of all U.S. fire deaths occur in the home. Home fire sprinklers can control and may even extinguish a fire in less time than it would take the fire department to arrive on the scene.

Only the sprinkler closest to the fire will activate, spraying water directly on the fire. In 84% of home fires where the sprinklers operate, just one sprinkler operates.

If you have a fire in your home, the risk of dying is cut by about one-third when smoke alarms are present, while automatic fire sprinkler systems cut the risk of dying by about 80%.

In a home with sprinklers, the average property loss per fire is cut by about 70% (compared to fires where sprinklers are not present.)

We also offer customers’ precision engineered and optimum functionality based Fire Pump Room. These are designed to deliver optimum functionality standards in diverse industries.

Further, as these are manufactured using quality components & spare parts, these are also wear & tear resistant as well as deliver optimum performance standards. We can also offer these in different specifications to fulfil diverse usage needs of our clients.

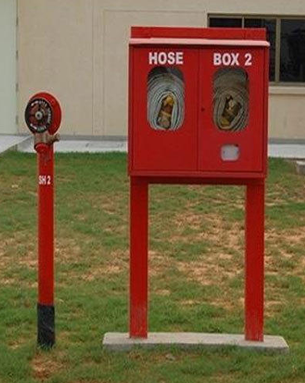

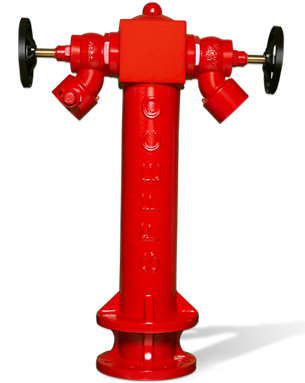

We offer a range of FIRE HYDRANT SYSTEM and YARD HYDRANTS

with all required accessories. Some of the feature of this systems are as follows -

The Hydrant System comprises of AC motor driven pump sets with all required accessories including valves, instrumentation and controls etc. Complete in all respects. An automatic hydrant system is furnished covering the areas completely from independent.

Pipe work from the fire water pump set.

The hydrant pipe work is remaining pressurized through the proposed jockey pump taking care of any leakages in the system pipe lines, valves and fittings.

The hydrant system is kept charged by pressurized water at approx. 7 Kg. Cm. Sq. at all times. In the event of fire when any of the hydrant valves in the network is opened, the resultant fall in pressure system is enabling starting the AC MOTOR driven fire water pumping set through pressure switches automatically. One diesel engine pump shall be standby pump serving hydrant system. Apart from the automatic starting of the pump sets, provision shall be kept for manual starting also. Shutting down of the pump sets shall be manual.

Hydrants inside the building is furnished with required accessories such as hose pipes with instantaneous gun metal couplings and g.m branch pipes located in hose cabinets. The hose cabinets is wall / column mounting type, constructed out of 18 gauge mild steel sheets.

The internal hydrants ( Landing valves) is single headed type taken out from 150/100 mm dia riser through suitable reducer. The outlets is gun metal and confirm to IS : 5290. HT Hose reels is firmly held against the wall by suitable heavy brackets and supports. The hose reel is swinging type ( 180 deg.) and the entire Dum reel etc. is as per IS : 3876. The rubber tubing is best quality ( Dunlop ) and the nozzle is 6 mm dia. Shut off type. The equipment shall be out of one of the approved makes

The hydrant main is laid in the form of ring main. The hydrant risers is terminated with air release valves at the highest points to release the trapped air in the pipe work.